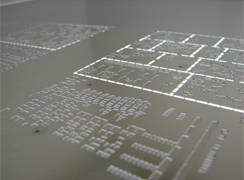

Multilevel or StepDown stencils utilize two manufacturing technologies, laser cutting and chemical milling. One ensures precise aperture geometries and the other ensures smooth and consistent thickness transitions in one homogenous material.

It remains the only cost effective and repeatable process for achieving maximum paste volumes and height for targeted components without sacrificing printability for ultrafine pitch components on the same assembly.

Guidelines

Keepaway Distance: The most common question. Obviously, the more distance between the openings on the different step thicknesses of the stencil the better. But also, it depends upon the depth of the step. If the difference in thickness is only .001” the gap between areas can be smaller than stencils requiring a more significant step such as .003”.

In general, we would like to see 0.150” clearance per .001” step in thickness. This is of course wishful thinking since those in contract assembly rarely have any say in board layout.

Keep in mind, the recommended clearances are not manufacturing restrictions but printability suggestions based upon feedback from our customer base.

Manufacturing Sequence:

- CAD designer will design the areas to be stepped down. They do not design the thick area.

- Step areas and alignment points are imaged on film by a laser photoplotter.

- Film and foil are aligned imaged and chemically etched.

- Foil thickness is verified and alignment is checked.

- Foil is loaded into LPKF G6080 where data is digitally matched up to target points then cut.

- Foil is EpoCoated and mounted in the appropriate frame.

Uses for Stepdowns: Stepdowns are indicated where the stencil must accomodate two classes of parts. Firstly, those that require very minute stencil openings which need thin foil thicknesses to maintain consistent and repeatable printing. And secondly, those components which either must have paste volumes or heights only achievable through a thicker foil.

Back-Etch: While most of the multilevel stencils we manufacture are stepped on the squeegee side to achieve variances in paste deposition, another common use for multilevel stencils are to relieve areas on the stencil contact side to overcome surface features such as labels and printed wire traces which can affect stencil gasketing. Back etched stencils are also used in dual stencil print applications where the second stencil is back relieved for the initial stencil’s print.